Standing Seam Panels have side laps between the metal roofing panels that are arranged in a vertical position above the roofline. The metal roof panel system is secured to the roof substructure by means of concealed hold down clips attached with screws to the substructure, except that exposed fasteners may be used at limited locations, such as at the ends of the panels and at roof penetrations. The design of standing seam roof helps eliminates leaks because it is almost “seamless.”

Smooth metal roofs are particularly good for these areas that either do not have a greater slope then 2:12 or a 2 ft vertical rise for every 12 ft of horizontal run. A shingle roof needs to have a minimum slope of 2:12 or it will not drain properly. Metal roofs only need ¼:12 slope because the water runs faster on the ultra smooth solid surface. High slope roofs are often more expensive to reroof because of the hard angel so for maintenance reason a standing seam should also be considered in this situation.

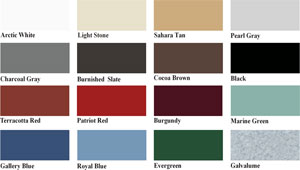

There are many different variations of Standing Seam roofing available in a variety of colors.